At least check out these packages so you’ll know for yourself. Your time investment learning the software is lost if you make a bad choice and wind up switching packages.įor those reasons, we include a section of “Almost Free” software that we think might be better than the free software. Remember these packages take time to learn. And sometimes free has sneaky hidden costs.

We spend so much time fighting with the free software that in the end, had we spent just a little bit on paid software, we might have come out a lot better. Other times free makes us choose vastly inferior solutions. Sometimes free is totally awesome and there are no strings attached. You’ll be spending more hours in front of your CAD and CAM Software than you will in front of your CNC Machine, so choose it carefully. You may have heard the expression, “There ain’t no such thing as a free lunch.” This may seem an odd way to get started, but I need to ask the question in all seriousness. For more on how these various packages work, check our CNC Router Software article. The Control Software is self-explanatory, but the other three programs are what’s needed to produce the g-code files that control your CNC Machine’s motions. We can make it simple using our G-Wizard Feeds and Speeds Calculator and cut out a big piece of your learning curve.

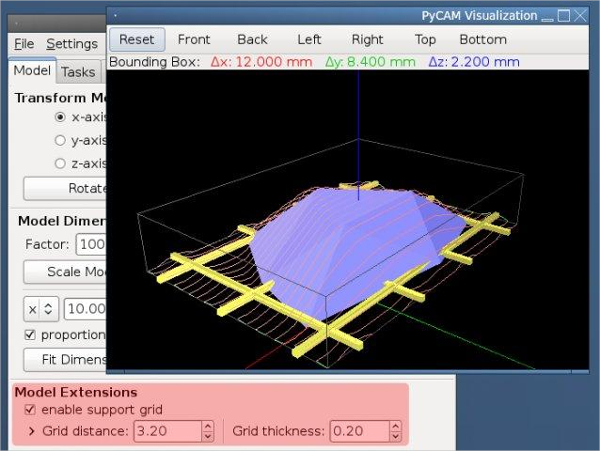

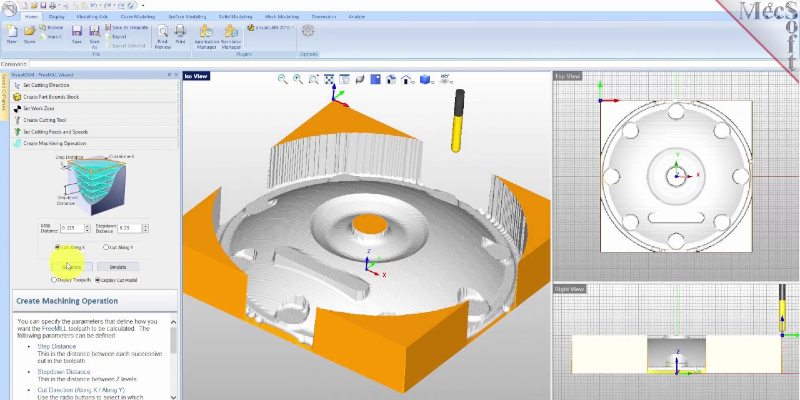

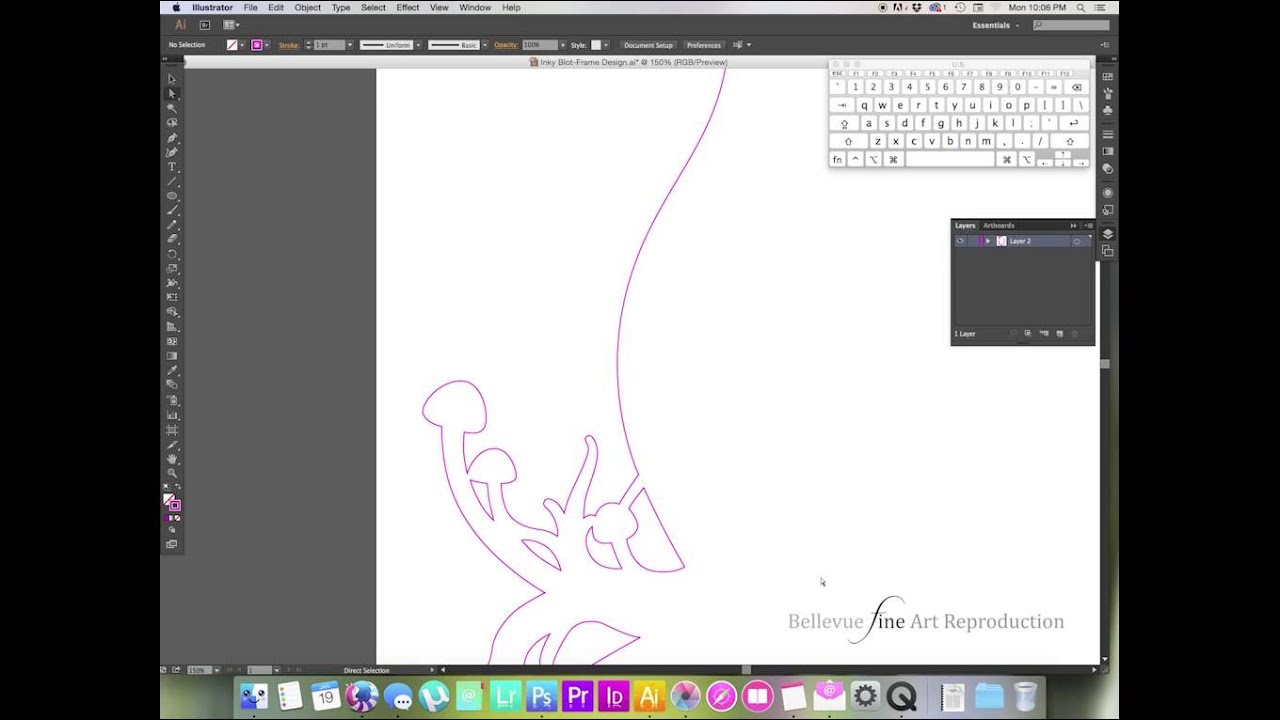

Feeds and Speeds Calculator: CNC’ers tell us that Feeds and Speeds is one of the hardest parts of CNC to learn.BTW, if you want to learn more about g codes, check out our free course. After creating a drawing or 3D Model, the next step in the CNC workflow is to use the CAD software file to generate g-code using CAM Software. CAD Software is what you’ll use to create drawings or 3D models of the parts you want to make. If not, the CNC Controller software we list below is excellent, especially for CNC Routers. If you bought a machine assembled or as a kit, it may very well come with CNC Controller software.

This is the software that actually runs your CNC Machine. There are many kinds of software for cnc, but the minimum software you will need includes: Here’s the lowdown for anyone who is a CNC Beginner.

0 kommentar(er)

0 kommentar(er)